How the healthcare industry joined forces to discuss healthcare construction as we emerge from one of the industry’s most tumultuous years in recent history.

Stories

Classical Music Revitalized the Soul of a Historic Kansas City Building

There has always been a song in the Kansas City air. From the founding of the first Kansas City Symphony in 1911 through the birth of jazz in the 1920s, music has been at the heart of the city’s history.

Time passes and society changes, and so does the city and the melodies it plays. But the music remains a constant thread connecting Kansas City over decades, across state lines, through hardship and prosperity.

“It’s a reminder that while our future is unpredictable, our past holds the key to what keeps us together … and there’s nothing like music to bring Kansas Citians together.” —

So when the Kansas City Symphony began looking for a new headquarters to accommodate its musicians, staff and the public, it took that thought to heart.

“Everything we do as the Kansas City Symphony is rooted in history and art and in relating what was to what is,” said Danny Beckley, Executive Director of the Symphony.

- That meant rather than raising an existing building to make room for something built to spec, the organization prioritized finding a historic space and transforming it into something practical for today and adaptable for whatever comes tomorrow.

And it only had to look out the windows of the Kauffman Center for the Performing Arts to find a new home to fit that mission perfectly.

- The historic Webster School, which most recently operated as an upscale restaurant and as retail space shuttered by the pandemic, sits on the south lawn of the Kauffman Center and was waiting for new occupants.

Beckley recognized the importance of working with architects and designers who shared a similar commitment to honoring the city’s history while modernizing infrastructure to meet the needs of the people who move within it.

We partnered with the Kansas City Symphony and Helix Architecture + Design to create just such an environment within the Webster School, which dates to 1885 — originally the oldest structure in the Kansas City public school district.

The former classrooms “really wouldn’t be conducive to anything more than bullpens, so we had to think creatively about how to use this building,” said Alissa Wehmueller, Principal, Helix/Architecture + Design.

“The team wanted to do “two things at once,” Wehmueller said. “Maintain the historic quality of the building [and] achieve the program and make it work for the symphony.”

“DIRTT walls became a really great solution,” said Beckley, to the question of how to incorporate private offices without permanently adding any structure that didn’t feel authentic to the building.

DIRTT creates an environment that reflects a fusion between the ornate features of the Richardson Romanesque building and the contemporary architecture of the Kauffman Center.

The glass DIRTT walls complement the Center’s iconic glass atrium and segment the building to make it suitable for the symphony’s needs, without hiding its original features.

“They brought a polished, elevated feel to this space,” said Wehmueller.

That constant collaboration between the symphony, the building owner and their partners has given new life to a historic building and a new home to Kansas City’s rich musical history.

“There is nowhere the symphony would rather be than in the Crossroads art district,” said Beckley.” — Beckley

“And to have them in a historic landmark? That makes it even better. The Webster School gives us the ability to introduce people to what we do and to open our arms and say, ‘we’re for you, too.’”

Designing the Future into Today’s Office Environments

As the business world constantly moves forward, the main goals remain growth and expansion. Yet growth inflicts demands on a business’s technology, staff, and even physical environment.

To foster expansion, businesses require larger teams, up–to–date technology, and an ever growing and changing office environment. Our team can help cultivate office conditions that change with you and the evolution of technology.

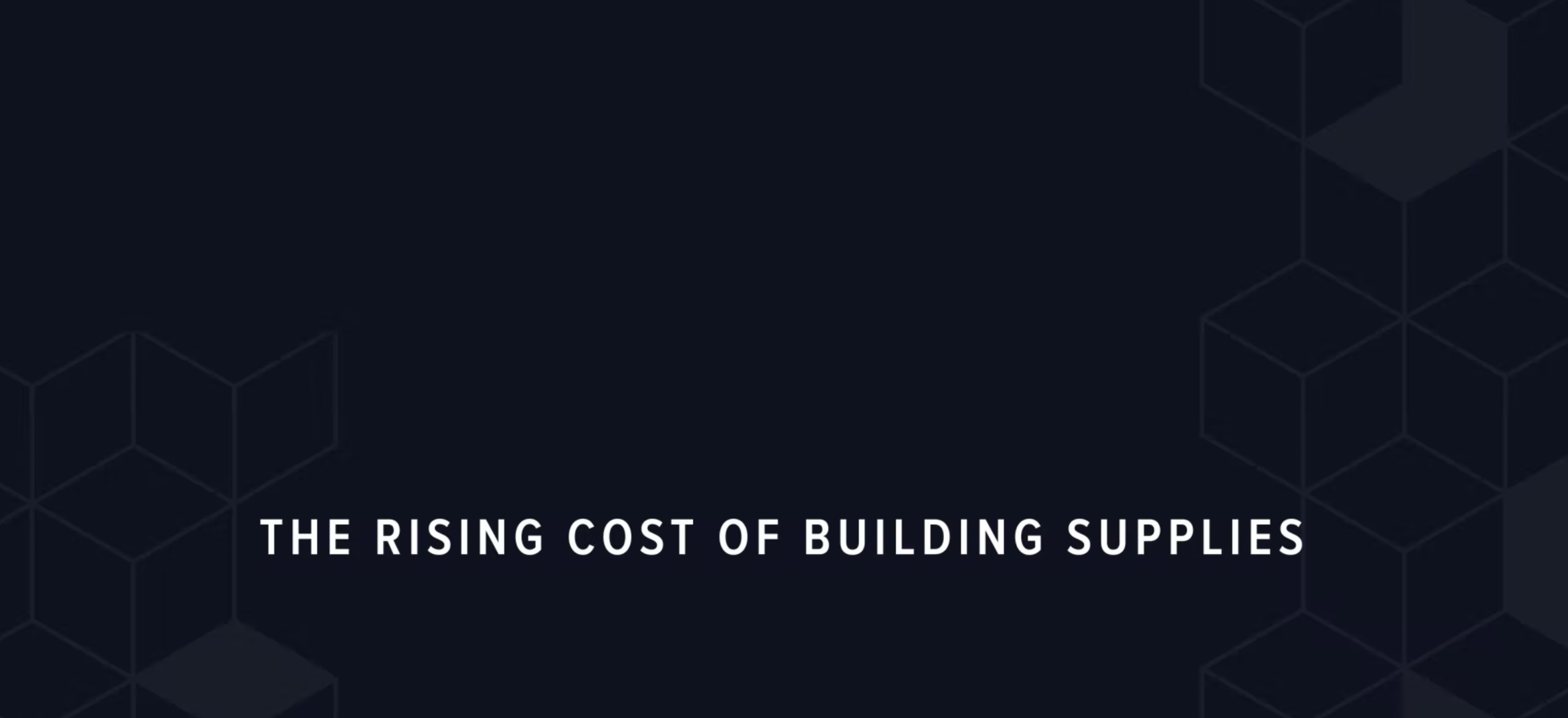

Vantage Credit Union worked with us in the past on a couple other smaller projects using DIRTT wall systems. When they began to outgrow their physical environment, they knew it was time to expand their new headquarters and contacted our team with a desire for a working environment employees would enjoy—something fun, different, expansive, and inviting.

New technology in prefab construction lends solutions to businesses. Using DIRTT wall systems, we crafted a custom working space of 20 offices, plus meeting, conference, and training rooms. Along the way, our team embedded wall technology where necessary.

The goal was to preserve the tall ceilings during the expansion. Despite the challenge, our team provided Vantage 13 feet of DIRTT walls. “We challenged them…they found a way to make all that work,” said John Hopkins, Chief Risk Officer at Vantage Credit Union.

Functional design makes doing the work of your business easier and more efficient while creating space for partnership. Now, the office designs are more cost and time effective. When the team at Vantage Credit Union saw their new headquarters, they were in awe of how quickly and masterfully a blank slate turned into an open and bright usable office environment.

Never has the demand of businesses been higher. We’re aiming to create meaningful working environments and offices that can help solve some of world’s biggest challenges. Let’s redefine office design and keep building strategically for tomorrow.

WATCH CASE STUDY

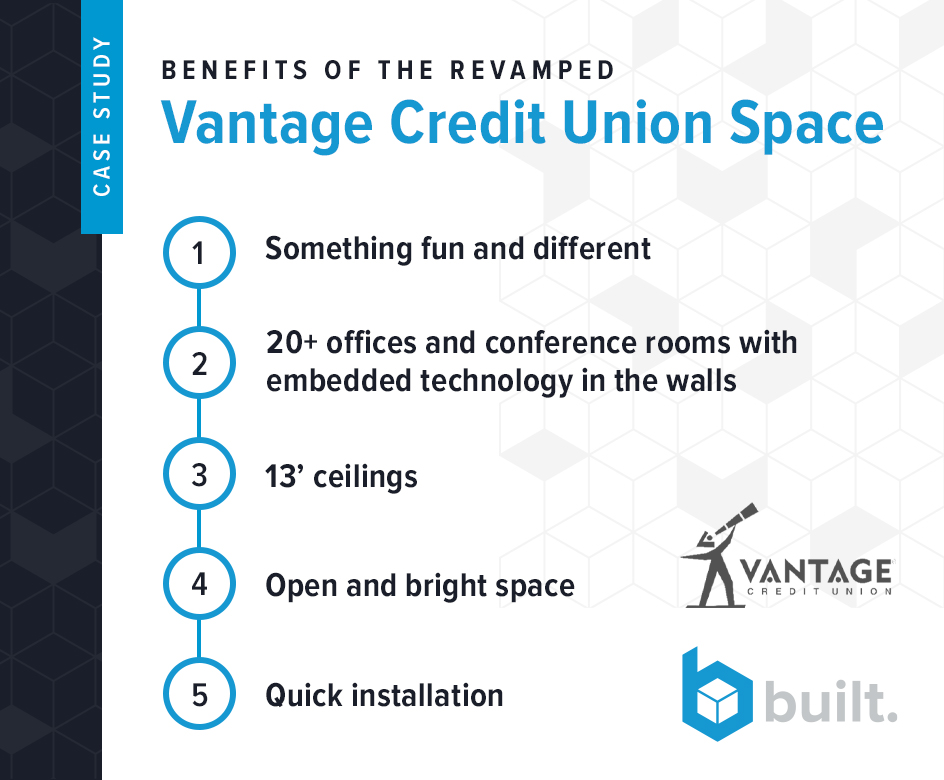

The Rising Cost of Building Supplies

Challenges bring opportunity, and today’s construction industry is no exception.

The construction industry looks wildly different today than it did before COVID. From labor shortages to price escalation, the changes have impacted everyone involved.

When asked about the rising prices of materials in the construction industry, Todd Missel, Vice President / General Manager at PARIC Corporation, answered, “I think what we failed to recognize is that the market had a surprise for us in terms of material escalation coming.”

In 2020, the industry hit a stopping point. Missel explains the drastic, swift changes, “Investors and developers got cold feet regarding their deals. Lenders did as well, and most of us experienced between a 20 and 30 percent decrease in revenue, nearly overnight.”

Though the revenue took a hard and fast hit, other changes hit much later.

A year after COVID began, the price of lumber increased by 300-500 percent. The raw materials industry was, like most other industries, impacted by staffing shortages. And those shortages created problems on both the supply chain and material delivery side of commercial construction, resulting in steep price increases.

Along with the price increase of supplies, companies were scrambling to forecast project intake of projects as pent-up demands and other factors were resulting in never-before-seen influxes of projects. Before COVID, construction companies could gauge staffing bandwidth and product availability based on the time of year, but post-pandemic opened a floodgate.

Sherri Balmer, Business Development Executive at PARIC Corporation expresses that from the construction end, “There’s a need to continue things along. The horizontal construction is picking up so fast that we have to work hard to keep up with it.”

Now, commercial construction operates at an even faster rate. While the pandemic forced people to stay home, the projects keep picking up. The more time people had at home, the more time they spent considering home renovation projects.

With a shortage of supply and labor and an increase in prices, construction businesses are realizing they need to think ahead and lean into nontraditional construction methods.

As Missel looks ahead to the next five to ten years, he expects clients will want to know more about maintaining deal costs.

And he sees this challenge as an opportunity for those working in prefabrication construction. Missel explains that prefab construction companies will be able to “use those principles of production from manufacturing to drive waste out of our supply chains, which will help drive value into projects. And we seek those partners who are willing to think outside of the box.”

Prefabrication companies were already thinking and performing with today’s solutions in mind before the pandemic even began.

Balmer expands on the path forward with the right partners. “We can come in as a team with PARIC and Built and educate them on what we can provide as a team and help them have an understanding of what this means on the ROI in the long run,” states Balmer.

HEAR THE CONVERSATION

Changing Together: A Commercial Real Estate Conversation

As the world shifted all around us this past year, spaces and how we spend time inside them also shifted.

Flexibility is both the biggest challenge and greatest area for opportunity in commercial real estate.

In-person white board sessions moved to video conferences and water cooler conversations became non-existent. Retail spaces had to close their doors for months and restaurants ran food to customers’ cars or homes instead of inviting them in.

Commercial real estate is no stranger to change. Between market shifts, economic fluctuations, and tenant lease agreements, those in this industry have always felt the need to stay on their toes.

Over the years, they’ve had to ask the right questions and listen. How do people want to shop? What kind of environment do people want to live in? How has work changed? Enter ever-changing technology and needs that fluctuate even more.

So while no one could’ve planned for the changes over this past year, if we’ve learned anything, it’s that the path forward isn’t rigid or cold. The path forward is through agility and through a people-first approach.

“Most people feel like there’s always this pendulum swing. From never going back to work again, to back at work – collaborating and innovating” – Chad Stafford, President, Occidental Management

“Spaces are going to change. It requires more flexibility, and the ability to change those dynamics quickly.”

It requires asking good questions, listening, and partnering with those that care. It requires a real understanding of the impact the commercial real estate industry can make.

As people start moving towards more in-person white board sessions, quick chats at the water cooler about the weather, and enjoying meals inside their favorite restaurants, their needs and expectations will be different from what they were a year ago. And so will the needs of the tenants, owners, and managers of those in these spaces.

The spaces themselves may need to change, but one thing is always constant: there will be people inside them. And as long as those in this industry keep that at the top of their minds and at the forefront of any decisions they make towards change – we’re moving in the right direction.

HEAR THE CONVERSATION

Moveable Walls For A Sustainable Future

Commercial spaces can be a revolving door. Literally.

The average turnover for a commercial space is five years. That means any given commercial space could need an interior overhaul up to twice a decade. For building owners and leasing agents, that means time, money, and material waste going into the same space over and over again.

When it comes to tenants, change is inevitable — no matter what you do.

A new tenant brings different needs, and those needs mean costly renovations. Even the same tenant’s needs will change over time, and if the space doesn’t change with them, they’ll eventually seek greener pastures. These days, tenants want a space that isn’t just functional or productive. They want something that inspires; a productive space that people don’t want to rush out of at the end of the day.

At Built, we don’t view change as a challenge. We embrace it. Our solutions are designed to change. They also align with our belief in being environmentally friendly.

Software Led Solutions

The inherent value of our solutions are their amenability. Our custom environments are made to last, but we know that commercial space renovations are frequent. Even reorganizations within a company can create different needs.

With the help of ICE® software, DIRTT solutions offer easy flexibility and adaptability for a space. You can negotiate better rates with your landlord to stay longer, knowing your DIRTT solution will grow with you. For property managers, the solutions can be repurposed for new tenants. These changes could be as simple as changing a wall or two for personalization, or a more comprehensive overhaul.

Our solutions can be repurposed into the new designs or recycled if they aren’t needed. Unlike consumer tech products, our solutions don’t have generations. A solution installed tomorrow will forever mesh with future materials, allowing changes to be made without much hassle.

Innovative Sustainability

Our clients want to save money. But they also understand the importance of being good stewards to the environment. When it comes to the intention behind our custom environments as well as all the efforts and materials that went into making them, sustainability is front of mind.

Why is sustainability so important to us?

For one, our clients demand it, and what is sustainable is often cost-effective. But we’re also part of an industry that has historically been a big part of the problem.

Approximately 40% of all materials in the landfill come from conventional construction, renovation, and demolition. Just one commercial space can create a massive amount of waste due to numerous renovations over the course of its lifetime.

We are in the business of solving problems. Our solutions help clients create innovative and sustainable environments that can evolve with the needs of the space.

Recycled and Recyclable Environments

With off-site prefabrication, we require smaller crews and much less material waste. As our solutions are manufactured to the 1/16th of an inch, there is little waste from cutting or preparing materials on site. Any unused materials are recycled at the end of the process.

From the products itself to the design, manufacture and installation processes, our solutions are sustainable without compromising functionality or innovation.

Our clients create environments where people actually want to be, while also alleviating headaches for building managers dealing with constant change.