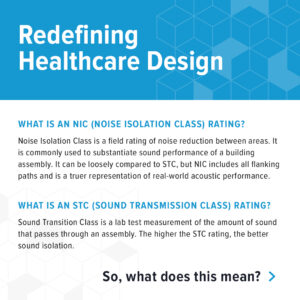

Sneezing. Coughing. The cries heard ’round the world that result from ever-dreaded vaccinations and shots. Private conversations between a patient and a doctor. News that a patient doesn’t want anyone else to hear.

We’ve all heard these muffled and sometime not-so-muffled sounds as we’ve coughed, sneezed, waited for our own vaccinations, and as we’ve whispered our own vulnerable questions to trusted doctors. If the walls of hospitals, doctors’ offices, and healthcare facilities could talk, they’d tell stories of heartbreak, celebration, healing, and comfort. But it’s fair to say that those stories aren’t for the walls’ to share.

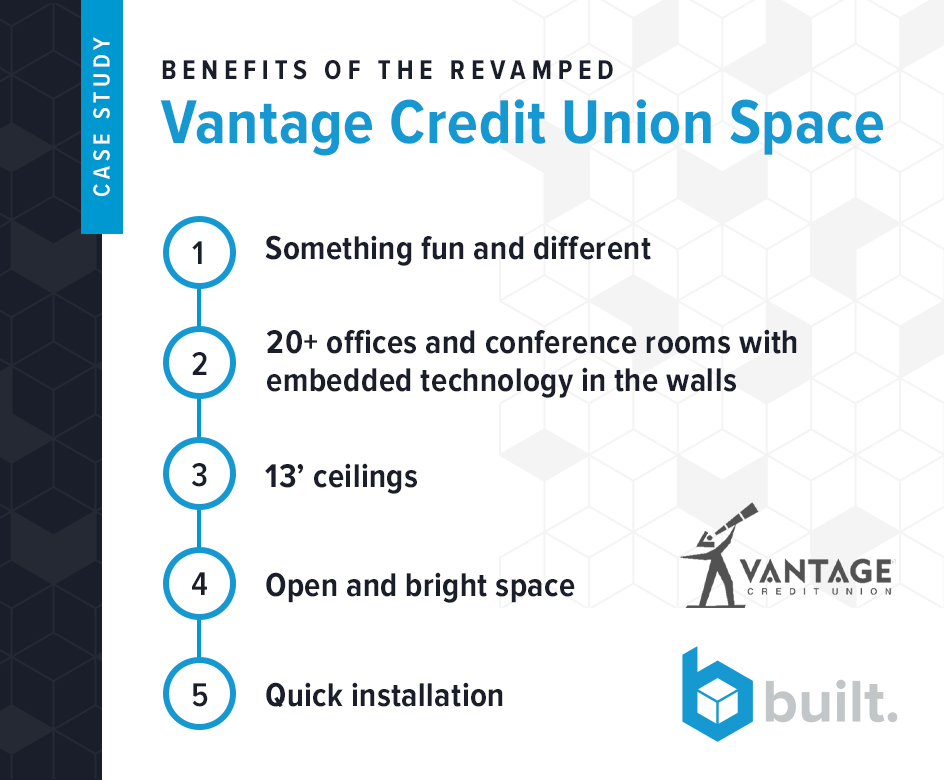

As healthcare facilities navigate this new decade and all that came from the most recent year, the need for patient-focused facilities has become an important topic of conversation. The need for adaptability, technology, innovation, and privacy.

The need for those stories that belong with the patient alone to stay with them. The need for walls that can keep a secret.

“It’s important to design these walls in healthcare facilities in a way that isolates sound as much as possible,” says Jeff Teel, Director of Acoustics at Henderson Engineers.

Confidentiality and privacy in healthcare construction starts with design.

“During design, especially at healthcare facilities, the sound isolation between areas can be very important for speech privacy and for patient confidentiality,” says Teel.

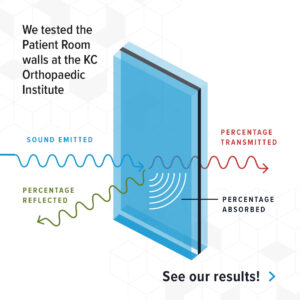

When walls are designed and assembled off-site, like in prefab construction, designers and contractors are able to begin with the end in mind. Unlike drywall that’s installed onsite, these prefab walls are designed using DIRTT’s proprietary ICE software. This software translates CAD and BIM/Revit to DIRTT, and these details translate factory data into installation instructions, which can be cut down to 1/16” of an inch, resulting in less sound transmission.

Sound transmission is measured by STC, or Sound Transmission Class, and is defined as the rating of a wall’s ability to block sound as it travels through the air. The higher the number, the quieter the walls.

Acoustical consultants like Jeff Teel perform field testing that measures the STC rating of a wall. You can watch a recent test Jeff performed for our client, Kansas City Orthopaedic Institute, here.

Because walls like DIRTT’s modular assemblies are designed and assembled offsite to a 1/16” of an inch, they typically carry higher STC ratings than traditional construction. For example, the walls we tested in the patient room at the Kansas City Orthopaedic Institute received a 50 STC rating, meaning loud speech on the other side of the wall is barely, if at all, audible.

2020 caused almost every industry to change, and change quickly. The healthcare industry has always experienced the need to adapt and change, but the past year has accelerated those needs and brought even more questions that need answers.

THE ACOUSTIC TEST RESULTS USING DIRTT WALL SOLUTIONS